Què és Lean?

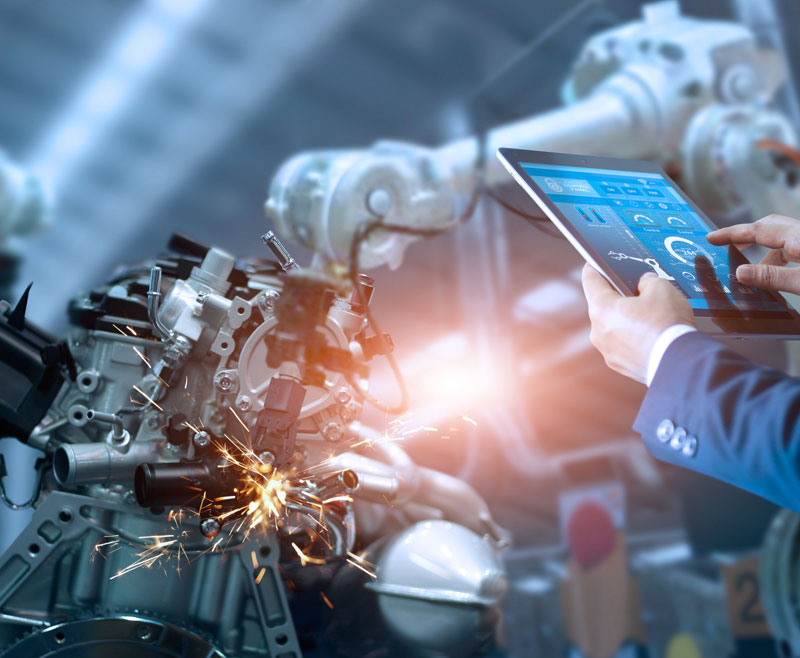

Lean Manufacturing has its origins in Toyota production system, it became popular in the 1970s, and was preferentially introduced to the global automotive industry.

The axis of Lean thinking is based on the constant elimination of waste with the aim of delivering the maximum value for the customer, it’s always focused in thinking about the customer. It means operating with more flexibility, less time, less waste, less surface area, less inventory, less storage and less human effort. In short, generate more value for the customer with minimal resources.

Today Lean has become a highly effective work philosophy, where its principles and techniques are being applied beyond production, in various activities and organizations, such as: logistics, pharmaceutical, hospital, services, construction and public administration, among others.

Fundamental concepts to understand philosophy are:

THE CUSTOMER

In Lean, everything revolves around the customer. Our goal as a company is to focus on the customer, and to give them maximum value. Their real needs must be understood in order to deliver the exact product, the desired quality, the right price, at the right time and the right quantity. This involves optimizing each process by visualizing the final goal, and not just visualizing the internal requirements.

VALUE

It’s the starting point of methodology, it consists in determine what is value from the point of view of the client. In reality, it’s the customer who defines the value with their specifications and needs. All activity we perform on the product or service must tend to comply with these value-added specifications.

WASTES

They are the opposite of value. In other words, any operation that does not add value and that our end customer is not willing to pay is a waste: defects, overproductions, rework, excess inventory, etc. The methodology has several tools in place to reduce and prevent these wastes and add value continuously. It is important that staff learn to search for, identify, and minimize waste in a systematic and continuous way.

PEOPLE

It’s one of the foundations of Lean methodology. Only if it has the full involvement of people can improvement actions be carried out. This participation must happen at all levels of the organization, from top to bottom. A Lean company encourages team spirit, staff development, and co-responsibility for success and failure.

PROCESSES

The implementation of the methodology focuses on processes, not functions or departments, and how to optimize the flow of products or services throughout the value chain. A Lean process is one that generates value.

IMPROVEMENT

It’s the essence of Lean thinking. Specifically, continuous improvement: the systematic search for more efficient processes in line with the business goal, or goal. It’s the responsibility of the whole group and applies to any area of the organization. No company or organization that has not integrated continuous improvement into its culture can be competitive in the medium and long term.

FLOW

Essential concept. The goal is to achieve that everything in the process flows smoothly between operations, always adding value, without any waiting or defects, trying to keep rhythm with the customer’s request.

PULL

Against to traditional way of working, manufacture everything possible, enters the Lean methodology with the concept “Pull”. This system means working at the customer’s rhythm, specifically his request. The amount of manufacturing and supply is limited to demand, managing to control stocks by increasing the production rhythm.

A una pime?

Large companies have applied the Lean methodology for many benefits, in the automotive world it is already a requirement. But for many “SMEs” (pymes) it remains an unknown strategy. How is it? If it’s beneficial, why has it not been implemented in small and medium-sized companies in Catalonia?

The use of Lean methods is available to everyone and requires a profound change in the way we think and act, which is easier in small businesses. The smaller structure is a competitive opportunity. Relying on the Lean methodology can achieve a differential positioning and a sustainable advantage that shouldn’t be acquired as a resource but should be understood as a capacity.

Everyone knows that small and medium-sized businesses are the driving force behind this country. We also know that the Catalan market is a very competitive market and that, generation after generation, it has adapted to several important changes. It’s even true when we say that Catalan culture flows a lot towards European culture. So, what is the reason why small and medium-sized companies in Catalonia don’t know or don’t want this service?

One of the main motivations for the birth of Leancat is to answer this question. The few existing companies that provide this service are consultancies or managers, Leancat doesn’t. We aren’t consultants or managers. We come to present the Lean philosophy, its advantages and benefits, and to participate in the implementation in its organization.

Què necessites?

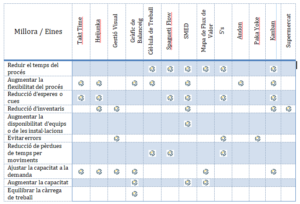

Lean methodology is a work philosophy that, through a series of tools, can be achieved gradually and systematically.

While we encourage the full implementation of the methodology, here are the Lean tools to apply based on the improvement needs of your organization: